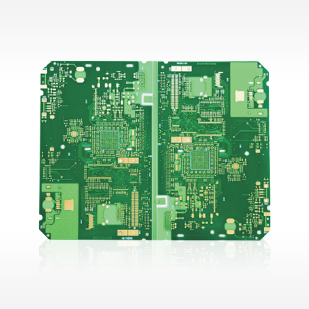

PCB Manufacturer in China

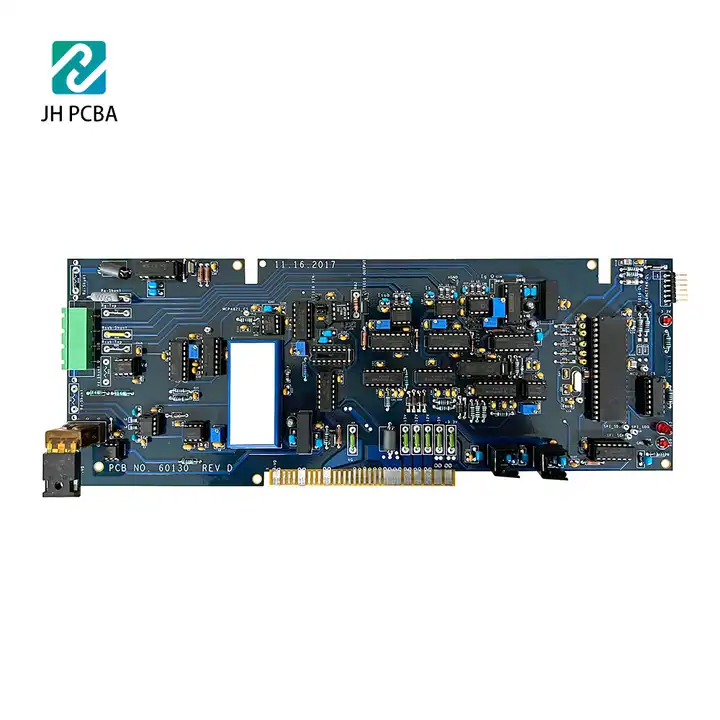

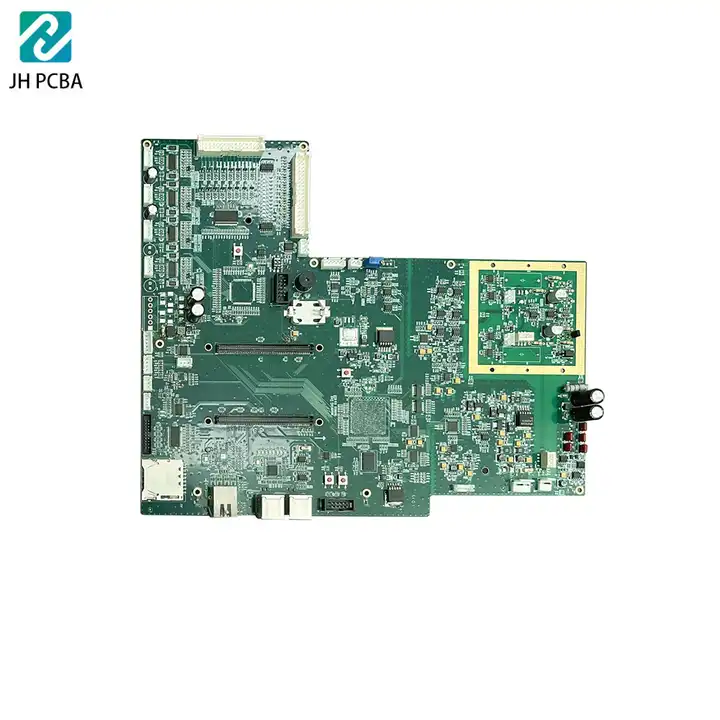

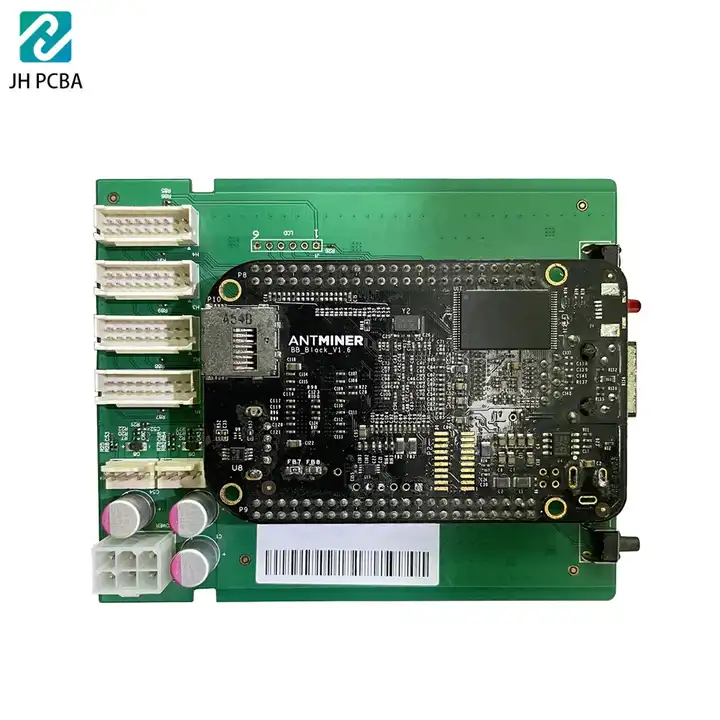

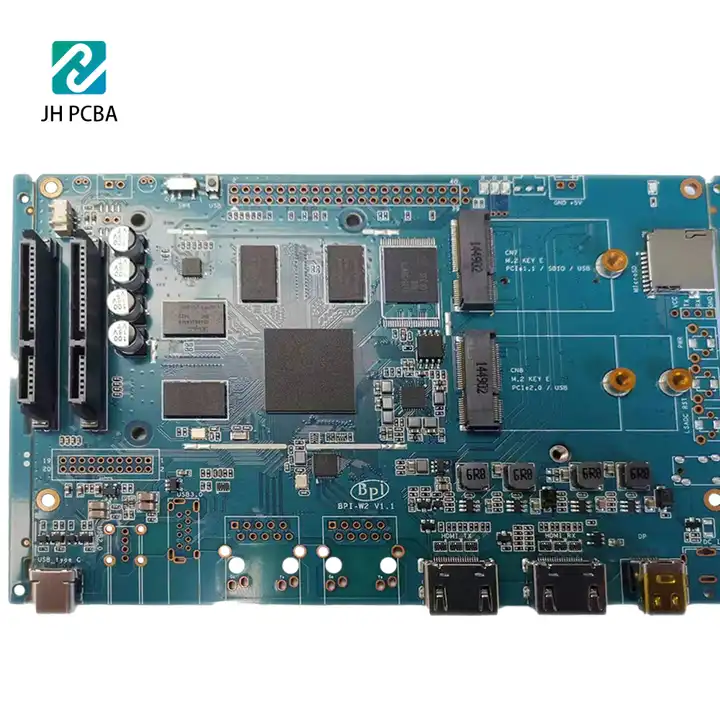

Since 2019, JinHua Technology has been a leading PCB manufacturer in China. We provide one-stop PCB services, including PCB manufacturing, PCB prototyping, PCB assembly, component sourcing, IC programming, and PCB testing. With more than 14 years in the PCB industry, we effortlessly satisfy your needs in terms of quality, delivery, low budget, and design requests.

Today, our factory cover an area of 5,0000 square meters, with a production capacity of 150,000 square meters of PCB per month. In order to manufacture high-quality PCB and PCBA, we take care of the entire production and logistics process, and strictly test before shipping. As a professional printed circuit board manufacturer, we have been awarded with ISO9001, ISO14001, IATF16949.

24H quick lead time

One-stop PCB & PCBA manufacturing service

On-line quote and order status tracking, easy & reliable

24*7 non-stop PCB manufacturing and assistant service

On-time Delivery with DHL, UPS, FEDEX

Supported by 60 professional engineers

Whole BOM list purchase management

NO MOQ! NO Higher Prices! We support OEM & ODM orders. Welcom to vist our factory for PCB projects.

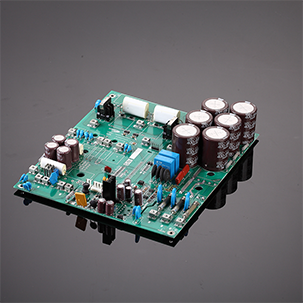

PCB & PCBA Supply

JinHua Technology provides one-stop PCB service, including PCB design & layout, parts sourcing, PCB manufacturing, PCB assembly and testing.

14 years of experience allow us to be a leading printed circuit board manufacturer, worldwide.

PCB Quality Certifications

Why Choose PCB Manufacturers JinHua

14 Years Experience

Jinhua has led the PCB industry for over 14 years, providing utmost quality OEM/ODM PCB & PCBA services. We have successfully handled large orders, and manufactured many precise PCB products in a shorter delivery time. We fully meet the specific needs of customers from various industries.

Advanced Technology

With increasing investment in the R&D center, we have grown faster. By developing PCB technology, we have explored new materials and manufacturing processes. Through state-of-the-art CAD software, our PCB design is capable of high efficiency and accuracy.

Quality Control

At Jinhua, we follow the most stringent QC system other than the basic visual check. We utilize testing and inspecting equipment, such as AOI, X-Ray, and SPI inspection to ensure top quality PCB in your hand.

24 Hours Customer Service

We support the comprehensive PCB service, including initial concept & design, assembly, and after-sale services. If you have any problems, be free to contact us. We will respond to your emails or messages in 24 hours.

55000

Sqm Factory Area

full-automatic production lines ensures high efficiency and lower manpower

888

Professional Staff

professional team with engineers and technical experts in PCB industry

5000

Satisfied Customers

global customers from Europe, America, South Asia, and China.

99%

On-Time Delivery

on-time EMS delivery for your PCB product

We provide a wide range of printed circuit boards and one-stop PCB assembly services, which are widely applied in high-tech fields, such as computers, electronics, automobiles, medical instruments, optics, telecommunications, industrial control, security electronics, power supply, LED, aerospace, etc.

Trusted PCB Components Partners

JinHua has purchased PCB components and PCB materials from many reliable and well-known original IC Producers, including NXP ATMEl TI or Arrow Electronics, Avnet, Farnell, Future Electronics, Chip1stop, WPG, Digi-key, and Mouser.

One Stop PCB Service

Delivering Quick Turn PCB, PCBA and Components

Service Advantage :

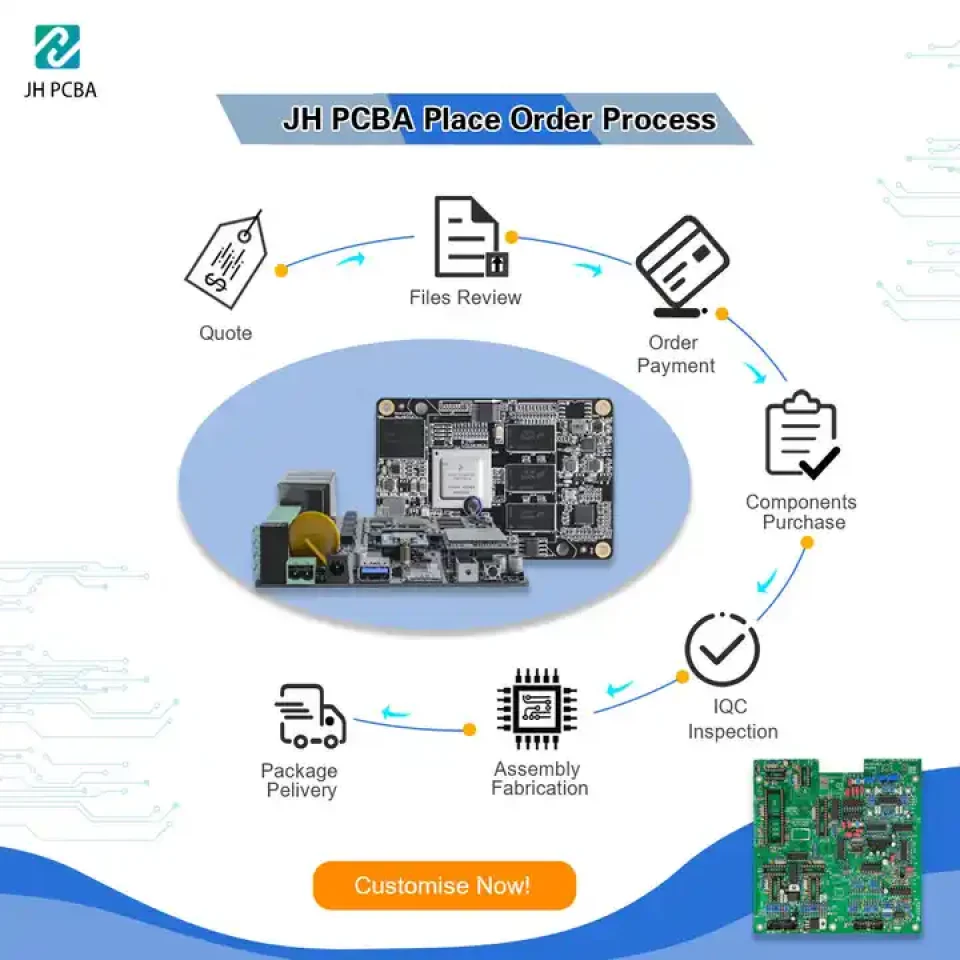

JinHua Tech is a professional one-stop PCB supplier. Our services range from PCB customization, material procurement, PCB production, patch processing, DIP plug-in, and delivery.

PCB Supply Service FAQ

As a professional PCB manufacturer, we can offer you PCB Design, PCB board manufacturing, Components or Parts Source, Surface Mount (SMT), Thru-Hole (THT), Functional Test etc. We can support one-stop Turkey PCBA service.

Gerber file and Technic requirements (material, surface finish treatment, copper thickness, board

thickness, and so on.)

- Gerber Files+BOM File+Centroid File(other names maybe: aka Insertion, Pick-N-Place, or XY Data).

- Gerber Files: including files: copper (track), soldermask, silkscreen, solder paste, drill, outline files.

Excessive parts do exist because we will ask for some percentage of overage for consigned/kitted orders, or we will buy more for the same purpose for those Tum-key orders. You can either ask us to ship back to you these unused parts together with the loaded boards, or keep them in our shelf for your next order. All up to you.

As to PCBA & PCB production, there are automated optical inspection (AOl) for each batch, X-ray inspection for BGA parts, first article inspection(FAI) before mass production.

1. Quick response to customers’ questions

2. If anything goes wrong with the printed circuit boards, we will help to solve the problems.

3. We also support PCB parts replacement for free & 0 shipping costs, making you feel at ease in cooperating with our PCB manufacturing company.

Jinhua has high standards and detailed reports for each part of the inspection and strictly chooses reliable PCB material suppliers.

Three main parts to control PC board quality as bellow:

1. IQC-incoming inspection for PCB materials

2. IPQC-process inspection

3. FQC-finished products inspection

We usually deliver the PCB product in 10-20 days, including 7-15 days for purchasing materials and 3-5 days for PCB assembly.

Yes. Our PCB manufacturing factory covers an area of 50000 square meters, equipped with 4 SMT production lines, 4 DIP plug-in lines, and 4 finished product assembly lines, with a monthly production of 150,000 square meters. It is on the 3rd floor, Building A, Zedali Industrial Park, No. 26, Jian’an Road, Tangwei Community, Fuhai Street, Baoan District, Shenzhen, China. We welcome you to visit at any time.

Your files will be kept safe. Client-owned files will not be shared with any third parties throughout the process.

There is no minimum order quantity requirement. PCB board company Jinhua can provide PCB services from quick-turn prototypes to mass PCB production.

As a leading PCB manufacturer, Jinhua provides one-stop PCB services, including PCB manufacturing, component procurement, SMT patching, plug-ins, post-soldering processing, housing manufacturing, final assembly, testing, and other value-added services to support our customers’ needs.

Blog

2.How to Prevent Solder Ball and Bridging Defects during the SMT Reflow Process.

2023-01-18

Get A Quote

– please feel free to quote us –

we will get back to you in 24 hours