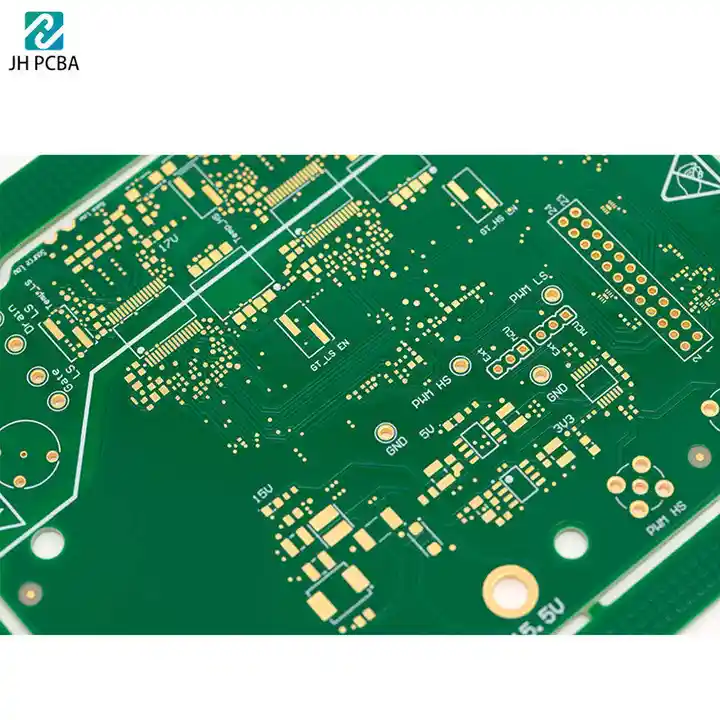

What is a Hybrid PCB?

A hybrid PCB is a type of printed circuit board that combines two or more substrate materials, such as FR4 and polyimide, FR4 and ceramic, or FR4 and aluminum base. These PCBs are gaining popularity in industries like aerospace, defense, medical, and telecommunications, where reliability, thermal management, and miniaturization are critical.

Hybrid PCBs merge the benefits of different materials to meet the specific needs of modern electronic devices. Let’s explore their advantages, applications, and key considerations for design.

Advantages of Hybrid PCBs

By combining different substrate materials, hybrid PCBs offer several significant advantages:

- Improved Performance: The use of multiple substrate materials allows for optimal performance in various aspects of the circuit, including thermal management, signal transmission, and power distribution.

- Design Flexibility: The miniaturization of electronic devices demands more compact and efficient PCBs. Hybrid PCBs meet this need by providing a high degree of flexibility in design and substrate material selection. For example, metal layers can be used for electromagnetic interference shielding, or ceramic materials can be included for high-frequency applications.

- Multi-Functionality: Hybrid PCBs can support multiple functions on a single board, simplifying system design. By integrating high-frequency and power circuits on the same board, the need for multiple boards and connectors is eliminated, reducing the size and weight of the device while improving reliability.

Key Design Considerations for Hybrid PCBs

Designing a hybrid PCB is more complex than designing a standard PCB due to the challenges of combining different substrate materials. Here are two crucial factors to consider:

- Material Selection: Different materials have unique properties, such as dielectric constant, surface roughness, and thickness. These properties significantly affect electrical characteristics like impedance, signal integrity, and crosstalk. Proper material selection requires designing interconnects with impedance matching and signal integrity in mind.

- Thermal Management: Hybrid PCBs often have high power densities, which can generate significant heat during operation. Temperature fluctuations may damage components or warp the board, leading to hot spots or thermal runaways. Effective thermal management, including thermal vias, heat sinks, or other cooling features, is essential to ensure long-term reliability.

Conclusion

Hybrid PCBs are a versatile and efficient solution for modern electronic devices, offering superior performance, design flexibility, and multi-functionality. While designing these PCBs may be challenging, understanding material selection and thermal management can ensure successful implementation. If you’re ready to explore hybrid PCBs, consider consulting experienced manufacturers to guide your design and production process.

FAQs

- What is a hybrid PCB?A hybrid PCB combines two or more substrate materials, such as FR4, ceramic, or aluminum, to leverage the unique properties of each material for improved performance and functionality.

- What are the main advantages of hybrid PCBs?Hybrid PCBs offer improved performance, design flexibility, and multi-functionality, making them ideal for applications in aerospace, defense, medical, and telecommunications industries.

- What challenges are involved in designing hybrid PCBs?The primary challenges include selecting appropriate materials and managing thermal performance to ensure reliability and functionality under varying conditions.

- What industries benefit the most from hybrid PCBs?Industries like aerospace, defense, medical, and telecommunications benefit from hybrid PCBs due to their need for reliability, thermal management, and miniaturization.

- How can thermal management be optimized in hybrid PCBs?Thermal management can be optimized by incorporating features like thermal vias, heat sinks, and efficient cooling mechanisms into the PCB design.