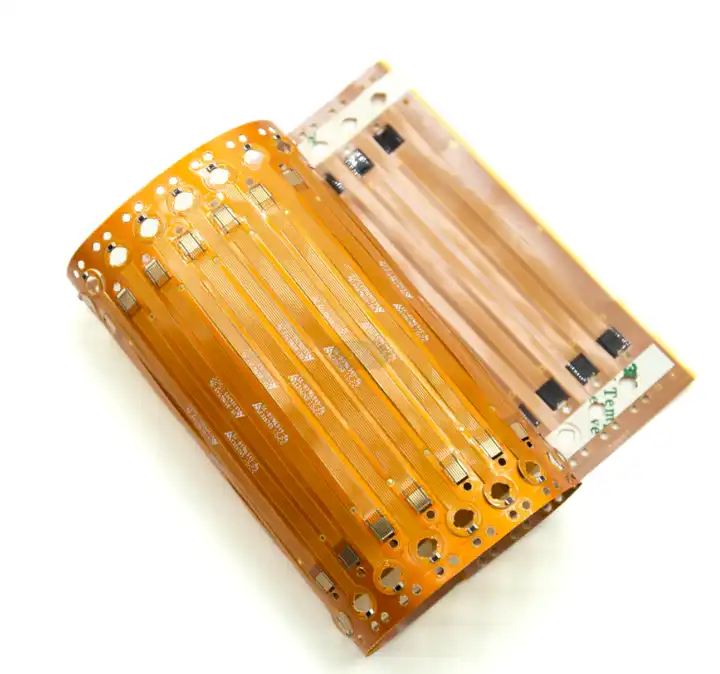

Category: Flex PCB

Flexible PCB Service

| Quantity (pieces) | 1-30 | 31 – 100 | 101 – 1000 | > 1000 |

| Lead time (days) | 5 | 7 | 12 | Negotiation |

Jinhua Costom Service

- Rich Experience: One-stop Flex PCB design & production factory for over 13 Years.

- 24H quickest lead time

- One-stop PCB & PCBA manufacturing service

- One-line quote and order status tracking, easy and reliable

- 24H*7 Non-stop production and support

- 100% On-time shipping with the best delivery from DHL/UPS/FeDEX

- 60 professional engineers support

- Whole BOM List Purchase Management

- PCB design and engineering service

No MOQ requirement; Competitive prices; Professional team for OEM & ODM orders. Get quotes Now!

| Supply Ability | 60000 Piece/Month |

| MOQ | 1PCS |

| Certificate | ISO9001/ISO14001/CE/ROHS |

| Layer | 1-12 Layers |

| Base Material | PI |

| Board Thickness | 0.1mm/0.13mm/0.15mm/0.25mm/1mm/Custom |

| Board Size | 250*1500mm/Custom |

| Copper Thickness | 1 OZ |

| Min. Hole Size | 0.2mm |

| Min. Line Width | 3mil |

| Min. Line Spacing | 3mil |

| Surface Finishing | ENIG |

| Testing Service | 100% AOI Testing |

| Application | FPC Connectors/Consumer Electronics/Telecommunications Electronics/Industrial Electronics |

| Shipping | DHL UPS TNT Fedex DHL |

| Packaging Details | Bubble package, EPE package, ESD Bag, Vacuum Bag |

| Port | Shenzhen, China |

What is Flexible PCB?

Flexible Printed Circuit Boards (Flex PCBs) are designed for compact, lightweight and innovative electronic devices. They gradually play important roles in the future, due to their unique performance, such as flexibility, durability, and versatility. Thus flex PCBs can be made in different shapes and spaces for emerging applications, providing versatile options and freedom in product design. Upholding excellent precision and professionalism, our flex pcb board will accomodate both commercial and industrial demands and requirements.

What are Benefits of Flexible PCB?

- Flexibility

Compared to traditional rigid PCBs, the flex PCB board boasts the greatest flexibility. Flexible PCBs can be bent, twisted, or folded to fit into spaces, while not compromising their performance and damaging circuits. Flexibility is one of the key and valuable characteristics of Flex PCBs, contributing to Medical Devices, the Automotive Industry, and more Electronic Devices.

- Saving Space

Flexible printed circuit boards are lightweight and thin, occupying less space and reducing their overall weight in compact designs. Flex PCBs play important roles in electronic devices with size constraints, like smartphones, tablets, and wearable devices.

- Durability

Flex PCBs are more durable than rigid PCBs, as they resist mechanical stress, movement, bending, and vibrations, promoting reliability and longer serving life. Featuring durability characteristics, flexible PCBs are widely applied in dynamic environments.

- Light Weight

The lightweight and flexible PCB boards are very suitable for electronic devices, the automotive industry, and aerospace, which highlight lighter weight for fuel efficiency and excellent performance.

Flexible PCB Solution

Flexible PCBs provide versatile and reliable solutions for many industrial applications, which require compact design and space. The flex PCBs are applicable in wearable devices, automotive industry, medical devices, aerospace and defense systems, automotive systems, and consumer electronics. With growing technology, flexible printed circuit boards will become more and more popular.