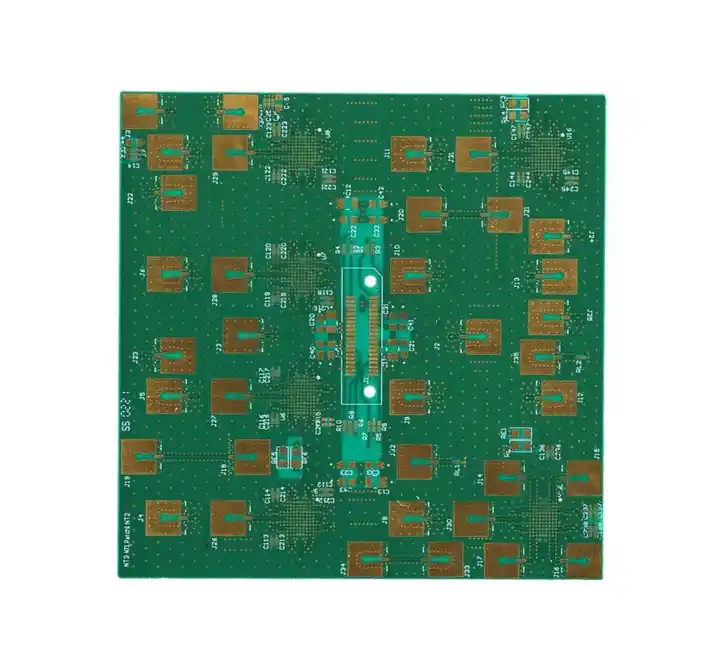

Category: PCB Prototype

-

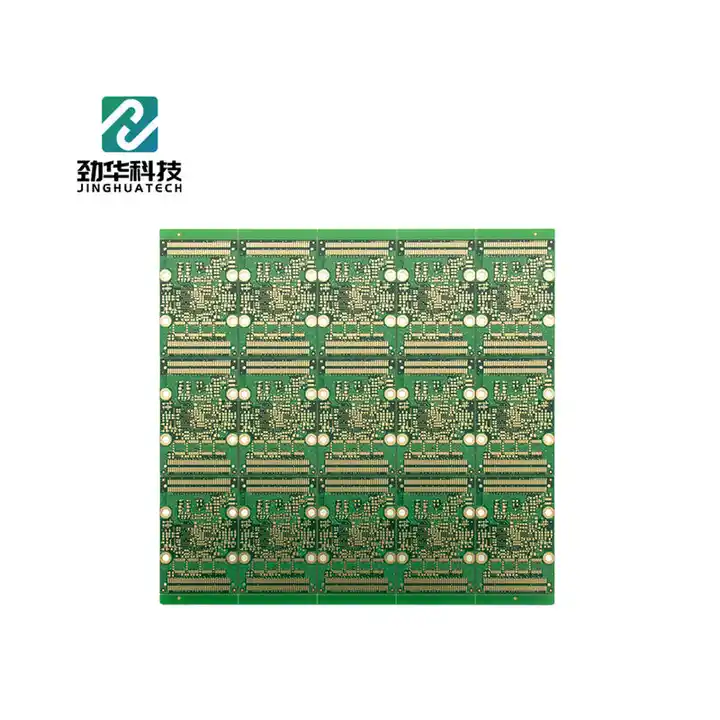

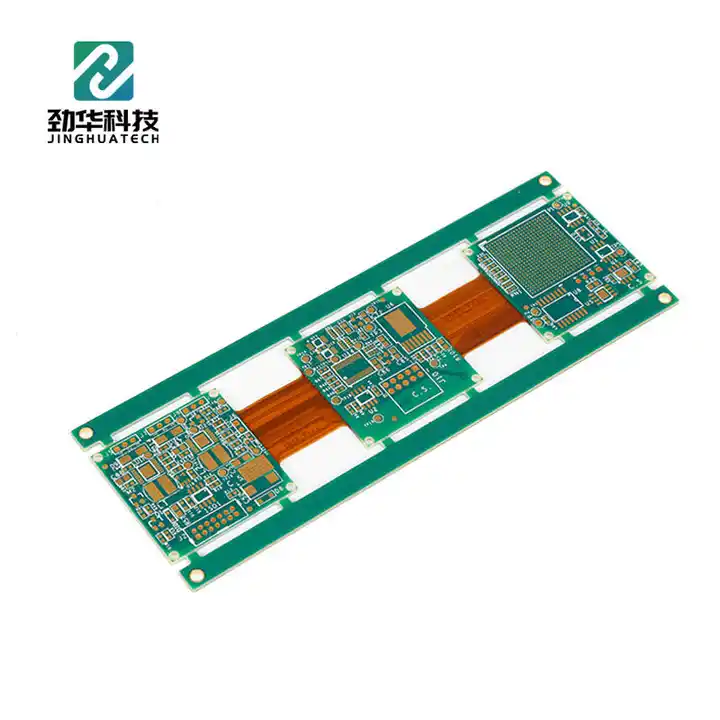

brand earphone motherboard multilayer rigid flexible printed circuit board pcb rigid-flex

-

China PCB Factory High Frequency Board Manufacturer Rogers 4003 PCB

-

Custom Product Gerber Bom File Quote Shenzhen Manufacturer Professional Design Service Prototype Multilayer PCB Circuit Board

-

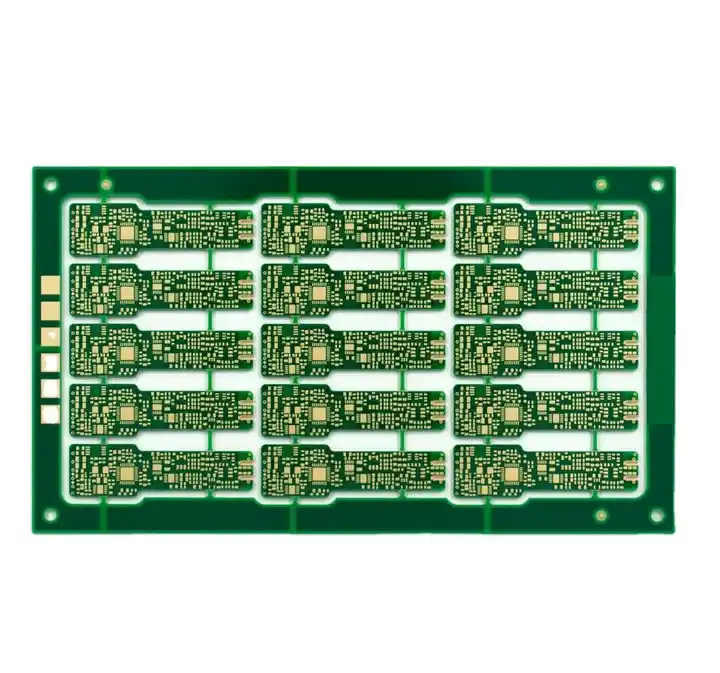

Customized PCB Four-layer 5G communication fingerprint module HDI rigid-flex board

-

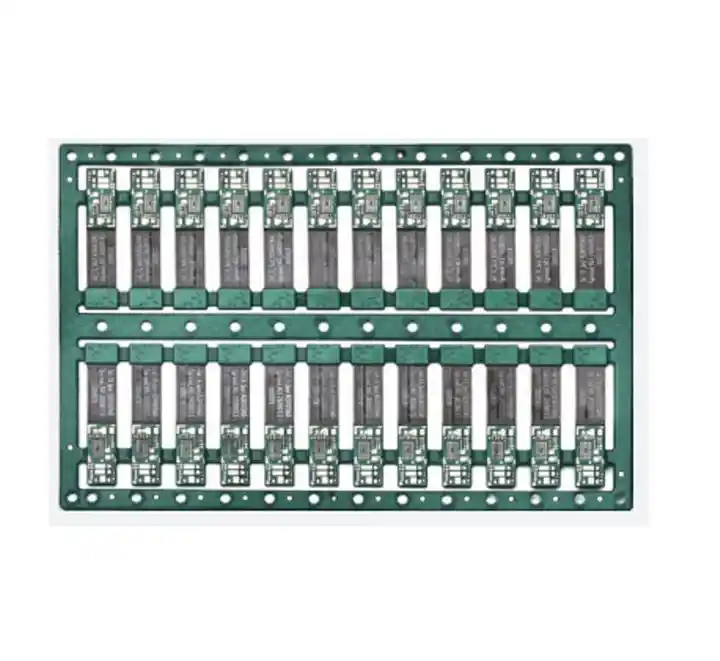

Electronic Pcb Layout Services Custom Pcb Manufacturing Transparent Flex Pcb Battery Oem

-

Hot sale bom gerber quote multilayer board oem custom electronic components circuit board pcb printing and assembly

-

JH-FPC-021 OEM High Industry Experience Flexible PCB Design Boards

-

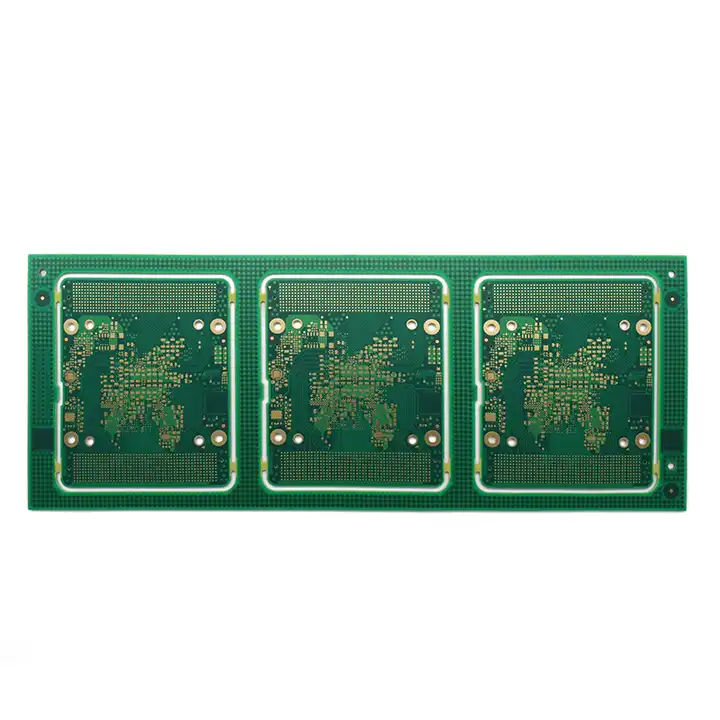

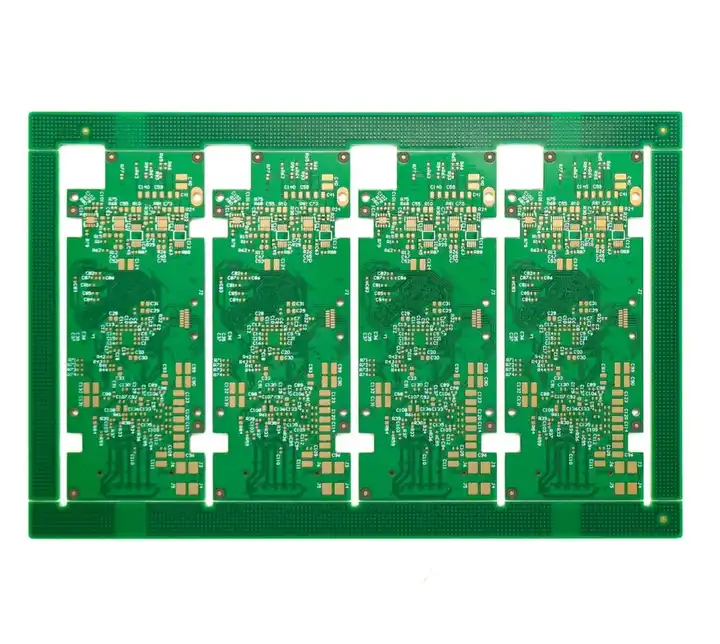

OEM Custom Ems Pcb Assembly 8 Layer Fr4 Vias Filled And Capped Tg170 Anylayer High Density Pcb

-

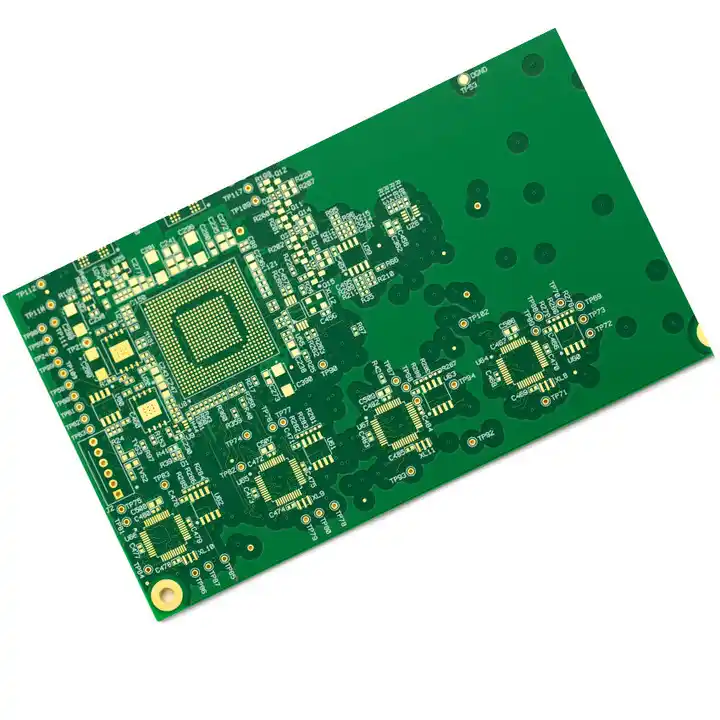

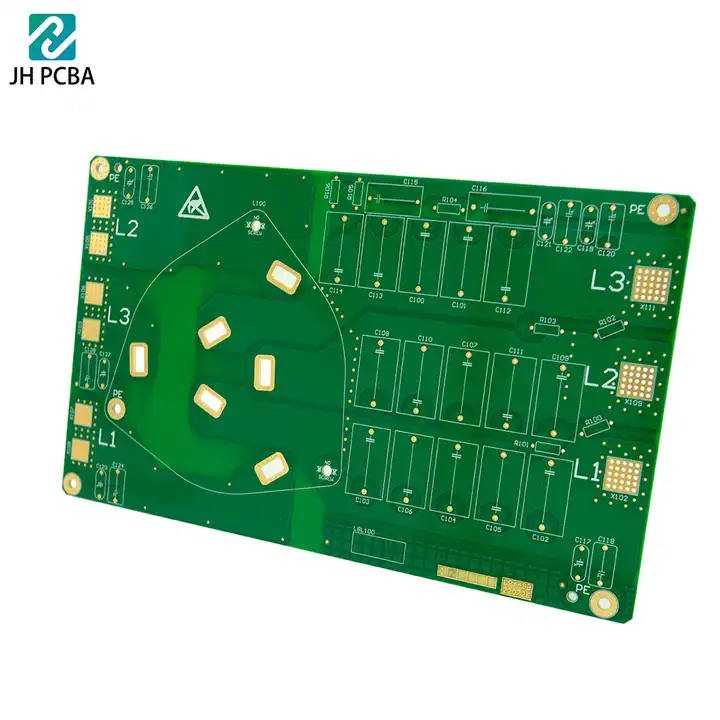

OEM Services 1~32 Layers Customized Multilayer RF PCB Design

-

One Stop PCB Services Rogers ro4350b PCB High Frequency High Speed PCB Design

-

Shenzhen Manufacturer High Frequency Board Substrate Rogers 4003 PCB Board

-

Shenzhen Professional Manufacturer Presensitized Motherboard PCB DIY 4 Layer PCB Factory

-

Support One-Stop Oem Service FR4 Motherboard Multilayer HDI PCB Manufacturing

-

technology manufacturer microvia hdi technology in pcb fabrication

-

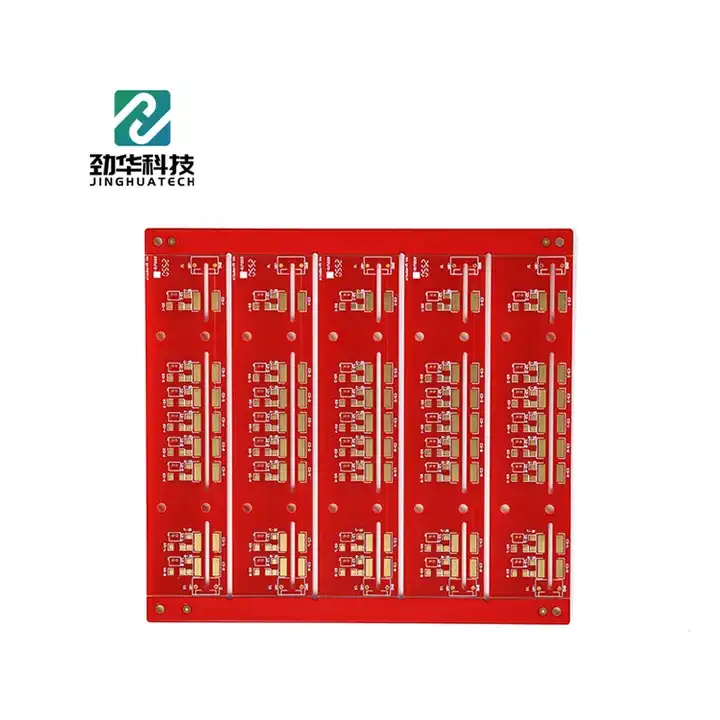

Top Sales OEM Custom Double sided Multilayer Rigid-Flex PCB Board

PCB Prototype Types

|  |  |  |

| Multilayer PCBs | HDI(High Density Interconnect) PCBs | Aluminum PCBs | Flexible PCBs |

|  |  |  |

| Rigid-Flex PCBs | High Frequency PCBs | Thick-Copper PCBs | Keyboard PCB |

PCB Prototyping Service

| Quantity (pieces) | 1-100 | 101 – 300 | 301 – 500 | > 500 |

| Lead time (days) | 3 | 5 | 10 | Negotiation |

Ability in PCB prototype

Our low-budget and quick-turn PCB prototype fabrication service allows you to explore different design possibilities. We focus on efficiency and quality: Large factories, automatic equipment, and professional engineers support your project; 24-hour sales and manufacturing speed up your PCB marketing; Fast delivery ensures that your orders are shipped on time.

- Over 13 Years of keyboard PCB manufacturing and design

- No minimum order quality of keyboard PCB order

- One-stop PCB manufacturing and assembly

- 100% AOI, X-Ray, ICT Function Test

- 24 Hours quick-turn prototype PCB fabrication and assembly

- Certificated by ISO9001, UR, ISO14000, ITAF16949, RoHS

- <0.2% defect rate of PCB products

- 7/24 Support and Production

- Professional engineer team to analyze Gerber before production

| Supply Ability | 60000 Piece/Month |

| MOQ | 1PCS |

| Certificate | ISO9001/ISO14001/CE/ROHS/IATF16949/ISO13485 |

| Copper Thickness | 1 OZ |

| Board Thickness | 0.2-8mm |

| Base Material | FR4/aluminum/Halogen free/High TG/Ceramic/Cutsom |

| Layer | 1~32 Layers |

| Testing Service | AOI/X-Ray/E-Testing/ICT Function Test |

| Surface Finishing | HASL/OSP/Immersion Gold/ENIG/Immersion Nickel/Gold/Silver/Palladium/OSP |

| Application | FPC Connectors/Consumer Electronics/Telecommunications Electronics/Industrial Electronics |

| PCBA service | SMD/SMT/DIP/Component Assembly/Turnkey PCBA Service |

| Shipping | DHL UPS TNT Fedex DHL |

| Packaging Details | Bubble package, EPE package, ESD Bag, Vacuum Bag |

| Port | Shenzhen, China |

What is PCB prototype?

Prototyping plays a crucial role in the design and fabrication of printed circuit boards. Before manufacturing a final PCB, we will make a PCB board prototype according to the design ideas. The PCB prototype service allows engineers to test and optimize designs before mass production, saving costs and improving efficiency. The best-performance PCB boards can’t be manufactured without PCB prototype boards. With growing electronic technology, PCB prototyping service will satisfy more complex and creative designs, and turn the ideas into final products.

What are Benefits of PCB prototype?

- Optimize Design

PCB prototype service is a path between design concepts and final PCBs. With prototype PCB boards, engineers can test the function and performance of PCB, and easily find out and solve the potential problems before mass production. After prototype PCB manufacturing, you will receive large numbers of the best PCBs in your hands.

- Improved Efficiency

The PCB prototyping phase allows engineers to upgrade and optimize the design based on testing and feedback. In this process, engineers can help PCBs achieve optimal performance through adjustment and refinement, such as component placement, routing, and signal integrity.

- Risk Mitigation

PCB prototypes help reduce the failure and mistakes in PCB design before mass production. It’s beneficial for you to save money and improve efficiency in the final PCB product.