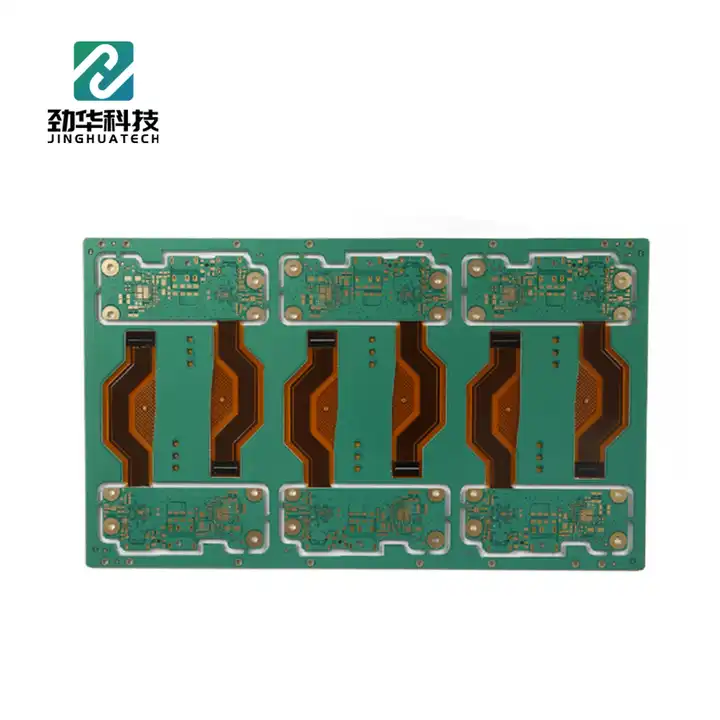

Category: Rigid Flex PCB

Rigid-flex PCB Service

| Quantity (pieces) | 1-100 | 101 – 300 | 301 – 500 | > 500 |

| Lead time (days) | 3 | 5 | 7 | Negotiation |

Jinhua Costom Service

- Rich Experience: One-stop Flex-rigid PCB design & production factory for over 13 Years.

- 24H quickest lead time

- One-stop PCB & PCBA manufacturing service

- One-line quote and order status tracking, easy and reliable

- 24H*7 Non-stop production and support

- 100% On-time shipping with the best delivery from DHL/UPS/FedEx

- 60 professional engineers support

- Whole BOM List Purchase Management

- PCB design and engineering service

No MOQ requirement; Competitive prices; Professional team for OEM & ODM orders. Get quotes Now!

| Supply Ability | 50000 Piece/Month |

| MOQ | 1PCS |

| Certificate | ISO9001/ISO14001/CE/ROHS |

| Layer | 1-12 Layers |

| Base Material | FR4+PI |

| Board Thickness | 1.6mm/Custom |

| Board Size | 250*1500mm/Custom |

| Copper Thickness | 1 OZ |

| Min. Hole Size | 0.15mm |

| Min. Line Width | 3mil |

| Min. Line Spacing | 3mil |

| Surface Finishing | ENIG |

| Testing Service | 100% AOI Testing |

| Assembly Service | SMD/SMT/DIP |

| Application | FPC Connectors/Consumer Electronics/Telecommunications Electronics/Industrial Electronics |

| Shipping | DHL UPS TNT Fedex DHL |

| Packaging Details | Bubble package, EPE package, ESD Bag, Vacuum Bag |

| Port | Shenzhen, China |

What is Rigid-flex PCB?

Rigid-flex printed circuit board is a great combination of flexible PCB and rigid PCB, providing versatility and stability. The rigid-flex PCB has these unique features, allowing it for a wider application in electronic design and fabrication, such as wearable devices, automotive systems, medical equipment, IoT field, and telecommunication. Rigid-flex PCBs are expected to play an important part in growing high-tech products, showing their unique advantages in design, materials, and manufacturing processes.

What are Benefits of Flexible PCB?

- Flexibility & Stability

Flex-rigid PCBs integrate both flexible and rigid characteristics in a single board, encouraging innovative electronic device design. The flexible sections of flex-rigid PCBs allow for compact designs with size constraints while rigid sections support more robust components. The flex-rigid PCBs will immensely promote more creative design.

- Less Space

These rigid-flex boards contribute to space efficiency, ideal for compact electronic assemblies. Their integration of flexible and rigid elements empowers three-dimensional layouts, reducing component waste and manufacturing costs. By enhancing production and design efficiency, flex-rigid PCBs boost sustainable and eco-friendly development.

- Reliability

Flex-rigid printed circuit boards reduce interconnects and solder joints, which enhances signal integrity and reliability, making them suitable for critical applications.

- Weight Reduction

Rigid-flex PCBs minimize the overall weight of electronics, which enables small and lightweight devices to add more function. Rigid-flex PCBs are ideal for aerospace and portable consumer electronics, supporting their good performance and reliable quality.

Rigid-flex PCB Solution

With their excellent flexibility, rigidity and versatility, flex-rigid PCBs make them ideal for electronic design and various delicate applications, such as smartphones, medical devices, cameras, aerospace, automotive systems, and consumer electronics. With the growing electronics market, rigid-flex printed circuit boards are expected to rise.